MS PIPES

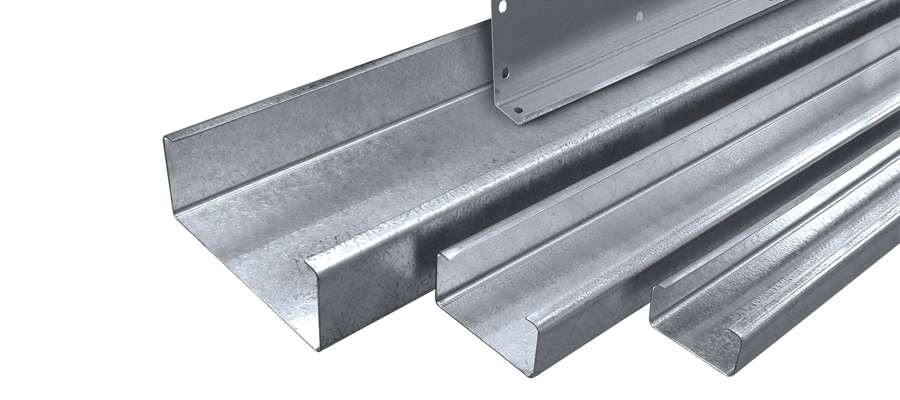

C Purlins

Steel help people to lead their life from a long period of time. To satisfy the needs of our clients, the company manufactures good quality TMT rods, C Purlins with modern machines.C purlins are easy to handle and fast to erect, versatility and durability are high

C Purlins are horizontal structures that are used to support the load from the roof deck or the sheeting. Purlin are most preferred material for cladding and support system due to its plane surface on one side and thus makes it very easy for installation on concrete structure or steel. Purlins are light in weight and most appropriate for simple construction.We are the best Steel Suppliers in Chennai provide the high-quality Steel Chequered Plates at an affordable price.

Z Purlins

Our company also focus on the manufacture of z purlins in the best quality and also for a wide supply. These purlins has a main role in the construction of tall roofs of a building as it supports the rafters as a beam.It has many features as it can be weld and used easily, it can be recycled easily and also it can be maintained in low cost, it is also used in the consumption of energy. It is used in solar lights and solar water heaters as it has the power of consuming natural energy from the sun.

Z Purlins are manufactured using cold roll forming technology to support roofing structures. The shapes of purlins can be customized into various flexible shapes facilitating various solutions. Z purlins are known to save upto 50% against the conventional use of Angles/Channels.

Product Specification:

Thickness: 1.6mm-3mm Material: HR/CR/GP/GL Hardness: 240-3250MPA

Features:

- Light weight

- High tensile strength

- Easy installation

- Available in Hot rolled /Cold rolled /Galvanised/ Galvalume

Advantages of C & Z Purlins:

- Customize length as per requirement and no wastage

- Fast rejection and easy handling

- Pre-punched to suit needs, hence no drilling/cutting required at site

- Perfect dimensions, strength and straightness to suit every customize requirement

- Cost advantage as decreased weight in comparison to regular MS Channels/ Angles

- Close tolerances on sectional sizes due to process of cold roll forming

- Saving 30-50% in terms of weight and steel usage.

- Saving 20-30% in terms of construction cost