MS or Mild Steel plates are widely used in various industries for their exceptional properties and characteristics. Understanding these properties is essential for selecting the right MS plates for specific applications. Let’s explore the key properties and characteristics of MS plates:

Strength:

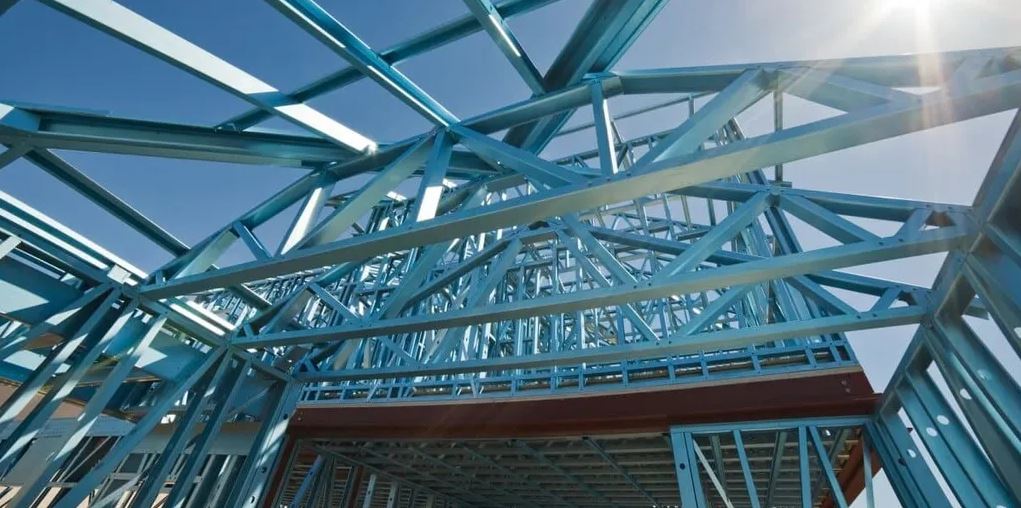

MS plates possess excellent strength, making them suitable for structural applications. Steel dealers believe that they can withstand heavy loads and provide structural stability and support. The high tensile strength of MS plates allows them to resist deformation and structural failure under extreme loads or conditions.

Ductility:

MS plates exhibit good ductility, allowing them to be easily formed, bent, or shaped without significant cracking or breaking. This property enables customization and flexibility in fabrication processes. It facilitates the creation of various structural components with complex shapes and designs, meeting specific project requirements.

Weldability:

MS plates have excellent weldability, allowing for easy and efficient joining with other steel components. This property simplifies the fabrication process and enables the creation of strong and reliable structures. JSW dealers say that the welded joints using MS plates exhibit high strength and integrity, ensuring the overall structural integrity of the fabricated components.

Machinability:

MS plates have good machinability, making them easier to cut, drill, and machine to meet specific design requirements. This property facilitates precise fabrication and enables the creation of complex structures with ease. The machinability of MS chequered plate contributes to efficient and cost-effective manufacturing processes.

Thermal Conductivity:

MS plates exhibit moderate thermal conductivity, allowing them to conduct and distribute heat efficiently. This property is advantageous in applications where heat transfer or dissipation is essential, such as heating systems or thermal equipment. The ability of MS plates to efficiently transfer heat helps maintain thermal equilibrium and optimal performance of the fabricated components.

Impact Resistance:

MS plates have excellent impact resistance, making them suitable for high-impact or dynamic load applications. They can absorb and distribute energy effectively, minimising the risk of structural failure or damage. This property ensures components’ structural integrity and safety even under sudden and severe loading conditions.

Cost-Effectiveness:

MS plates offer a cost-effective solution for various applications. They are relatively affordable compared to other types of steel, making them a popular choice for construction projects with budget constraints. The cost-effectiveness of MS plates does not compromise their quality and performance, making them an attractive option for a wide range of applications.

Availability:

MS plates are readily available in various thicknesses, sizes, and grades, providing various application options. Their widespread availability ensures easy sourcing and timely availability for construction projects. This availability allows for efficient procurement and ensures project timelines are met without delays.

Recyclability:

MS plates are highly recyclable, making them an environmentally friendly choice. Steel is one of the most recycled materials globally, contributing to sustainable construction practices and reducing the demand for virgin materials. The recyclability of MS plates helps minimise environmental impact and promote circular economy principles.

Steel suppliers in Chennai conclude that the MS plates possess desirable properties and characteristics that make them valuable in structural applications. Their strength, flexibility, weldability, and cost-effectiveness make them versatile and widely used in various industries. Understanding these properties allows engineers and designers to make informed decisions and select the appropriate MS plates for their specific applications, ensuring the creation of robust and reliable structures.