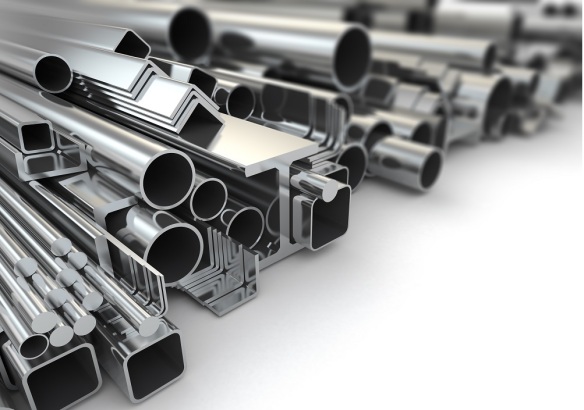

Steel plates are one of the construction materials happening in today’s world. The steel plates refer to the assembly of two parallel steel sheets, which are joined by either welding or tie bars. Steel plates are one of the most versatile construction components, which come in various shapes, sizes, widths, and breadths. Hence, due to its amazing versatility, the steel products, such as wires, rods, plates, and SAIL TMT price for bars, have gone by 117% in the last six years. It is also seen that the steel price can increase up to 30% by the end of next year. However, without the incorporation of steel plates, the structure may lose its stability over the foundation.

Hence, this blog will primarily look into the different types of steel plates used for construction.

Checkered Plates:

The foremost type of steel plate for construction is a checkered plate. These steel plates have angular patterns on them that are slightly raised. The angular patterns incorporated into the steel plates include designs of diamond, bean, round bean, and mixed. It is to be noted that these patterns are contained to offer an extreme grip for the people making lesser slips or falls. Hence, many MS steel suppliers in Chennai manufacture mild steel ideal for the elevator, industrial, and parking stairs or floors.

You can also find these steel plates at the corners of the door kick or walls to prevent scratches. These are easy to maintain as they resist elements like dust, liquids, and other kinds of dirt.

Galvanised Plates:

Another form of steel plate you can find in many construction projects is galvanised plates. The regular steel sheets undergo galvanization added to the immersion of molten zinc to increase the plate’s strength. It is incredible to know that these plates, despite their high strength, can be moulded into desired shapes, making them ideal for various projects.

Due to the extra-coating zinc, these plates have high resistance to wear and tear. Similarly, they can handle varying temperatures and hence finds their application in household products such as water heaters.

They are also a default option for making roofings and sheds, as they can last for a few decades because of their resistance to anti-corrosion.

Mild Steel Plates:

Thirdly, mild steel plates are a standard option for many projects. These are carbon steel and have excellent versatility, which can be welded into the desired shape. As these plates come in different thicknesses, they are an ideal option for structures or projects which include complex cross-sections or sections.

Similarly, these plates do not need special tools to remove or cut the MS plates. This MS chequered plate finds its application in the shipping and construction industry to make equipment and terminals for bridges, buildings or warehouses.

Hence, these are the primary steel plates commonly used in various industries depending on demands and purposes. Thus, approach Bharat Steel to avail bars, channels, or MS plate price in Chennai at a competitive rate.