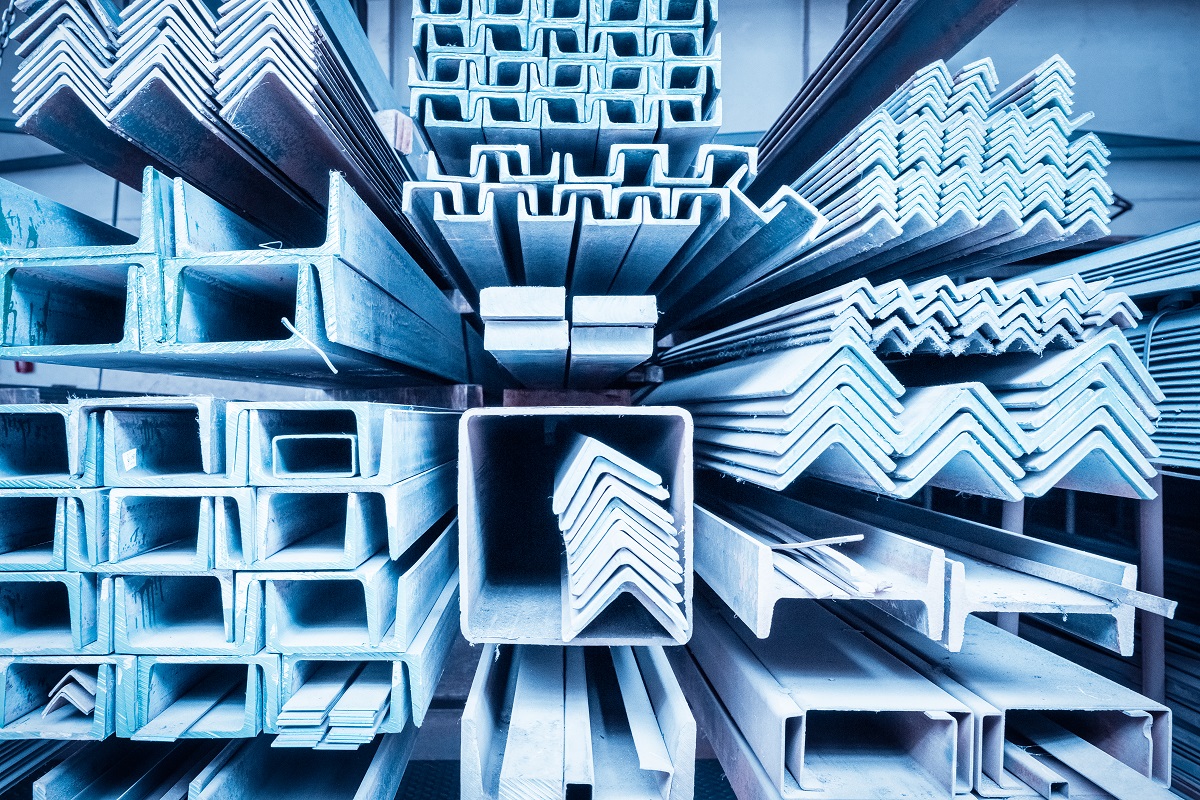

Steels are generally used in construction to make the building stand straight and strong, given any condition. The steel binds well with concrete making it both the properties stronger to sustain the weight and keep the building at the right place and shape. The steel used in building construction is usually straight and strong to uplift the buildings. Steels can be of many sizes, shape or texture as in general it is a metal after all. We at Bharat Steel, offer you a competitive SAIL steel price than other dealers without compromising its quality.

When it comes to steel it is highly necessary that we must use the right kind of steel for our buildings to stand tall. What if the best steel suppliers in Chennai told you could check the quality of the steel on site itself? Sounds intriguing huh? Then why wait let’s get started:

Check If Your Steel Manufacturer Are Test Certified:

Certification is everything as it shows the actual properties issued for a particular lot. Every steel manufacturing company should test their steel to see if their steel is manufactured rightly and if it could withstand any condition or test it would pass the test and would come out to be approved. With the help of that proof, you could relax and believe that your buildings are in good hands. Did you know the MS plate price in Chennai is where you could also check the price? They are the best manufacturers when it comes to steel in Chennai.

Look For The Grade That Has Been Given To The Manufacturers:

The grade of an average should be of FE500. This should be the basic grade of the steel. If it is lower than this you could prefer a better steel manufacturer who could give you the right grade steel like the MS steel suppliers in Chennai. The grade tells everything about the steel that is given as it helps us know if the steel is good or not. If the steel is really good it would be certified as FE500D. This could be the ideal steel for construction and you need not worry about the building as you have found the right manufactures of steel.

The Rebend Test:

The rebend test can be started of by bending the bar for 135 degree and observe on how the bar behaves when you place the rod in a 100 degree celsius water for over 30 minutes, if there is no issue with the rod bend the rod 157.5 degree and see if it cracks, if not then the rod is in perfect condition and is strong enough to withstand a harsh climate or weather.

The Rust Check:

Rust on steel rods are quite common but the quantity of the rust could damage the rods leaving it a bit brittle than other rods. The rusted rods could leave splinters if it’s over rusted. So get in touch with our steel dealers.