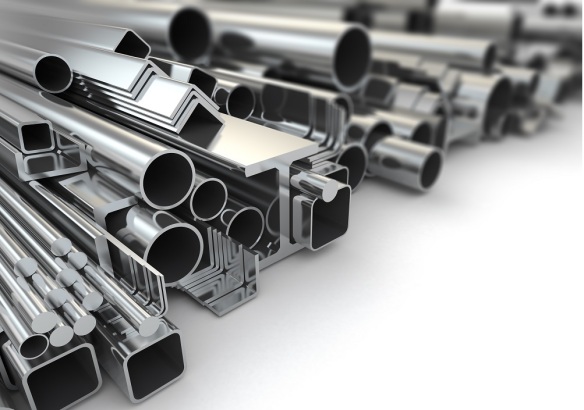

You would have certainly heard the term concrete at least a thousand times in your life. The term concrete is a mixture of water, cement, and aggregates such as sand, gravel, or crushed stone. The cement, water, and aggregates bind well to form concrete. It is this paste used in the building material to build structures and foundations. However, the concrete building can compress the natural but tension forces like loads, pulling, and pushing can crack them. Hence, steel suppliers in Chennai use reinforcement steel rebars or rebar to withstand the tension forces of the concrete. The rebars are the combination of steel wires that bond well with the concrete by reducing slippage. The rebars are made through hot-rolled treatment by using new steel billets or different steel materials. In some cases, rebars are made from steel scraps or railroad rails. These rebars undergo hot-rolling at an average of the 60,000-75,000 psi bar. Therefore, rebars play a vital role in concrete construction. Hence, in this post, listed below are some common types of rebars in the construction industry.

Carbon steel rebar:

The most common type of rebar, predominately used in the construction industry, is carbon steel. It is also referred to as the “black bar” because it corrodes when exposed to high temperatures and moisture. JSW steel dealers in Chennai even produce carbon steel rebars used for making beams, slabs, and many more. These carbon steel bars have a tensile strength of up to 40000 psi to provide sufficient tensile strength to the concrete. Hence, many constructors consider carbon steel rebar as the best for the buildings than other steel products.

Welded wire fabric:

Another common type of rebar used in construction is the welded wire fabric (WWF). It is a typical type of rebar found at every construction site. The WWF is a mesh of steel wires connected at right angles and welded electrically at the crossings. These rebars are used on the grounds, slabs, beams like SAIL TMT bar where the ground is well compacted. The heavier fabricated WWF rebars can be used on the structural floor slabs and walls. Hence, you can use these rebars on the concrete canals, road pavements, drainage structures, and many more.

Sheet-metal reinforcing bars:

Thirdly, the sheet-metal reinforcing bars involve several sheet steel pieces annealed and bent to form a corrugation at a one-sixteenth inch depth. These even have holes punched at regular intervals. Hence, these are suitable options for flooring slabs like MS chequered plate, stairs, and roofing.

Expanded metal bars:

The expanded metal bars or wire mesh rebars are the rebars where the steel sheet is sheared into parallel lines. The parallel sheets are expanded using various techniques to form a diamond or square shape between each cut. These types of rebars are used in light concrete construction like sidewalks, small concrete pads, and walkable surfaces.

Hence, these are the commonly used rebars in the construction industry to improve the strength of concrete buildings. Therefore, consider the suggestion shared in the post to choose the appropriate one for your construction.