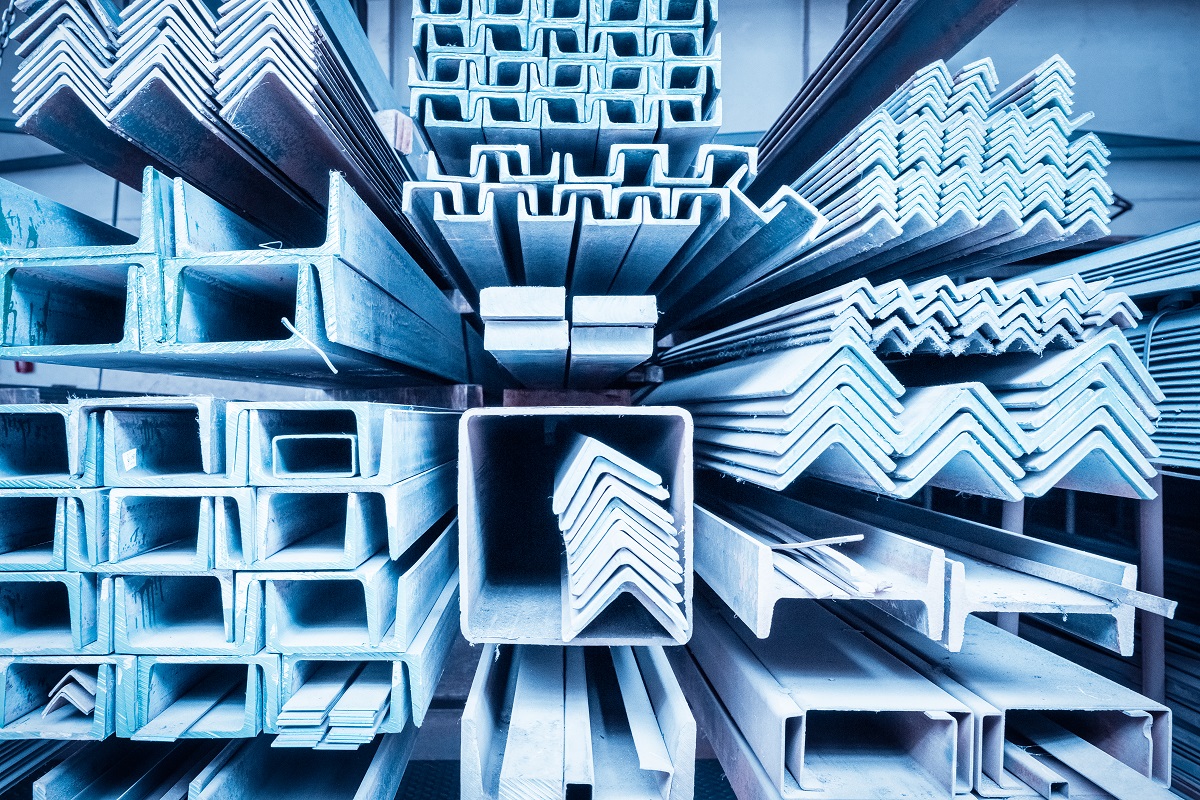

Have you ever heard of steel tubes? Steel tubes are similar to columns that are cylindrical tubes that are used from industrial to structural uses. At the first glance, you may find that the steel tubes and steel pipes are similar.

However, they vary from each other in every aspect. Generally, steel pipes are used for the transmission of oil, water, and natural resources. But steel tubes are used as a part of the construction industry to support the structures. Hence, steel suppliers in Chennai provide steel tubes in different shapes like square, rectangle, or circular to meet the building requirements. The properties of the steel tubes are similar to the steel pipes, and many steel dealers use only high-grade steel for these tubes.

These steel tubes are durable, have high tensile strength, and are made into desired shapes for structural adjustments. Hence, in this post, let us know the various applications of steel tubes.

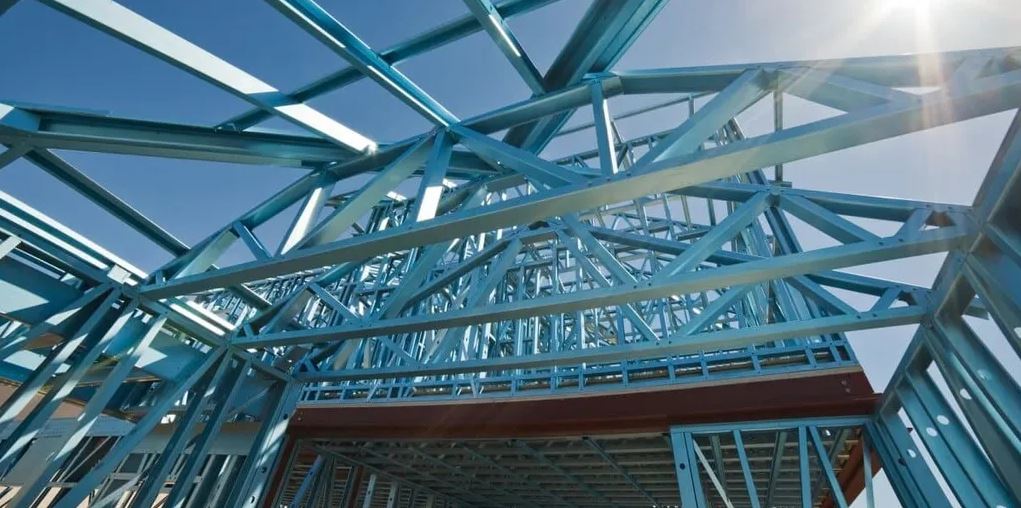

Columns:

The steel tubes are used in the construction industry as columns to support the structure. These longitudinal steel columns are used to bear the loadings of the buildings. Steel columns can be specially used for high-raised structures because they offer high stability and resistance to chemicals, abrasions, and fluids. So, building contractors use steel tubes in place of reinforced concrete. The prolonged exposure of concrete to moisture can make them weak and cause deformation. Thus, steel tubes are the best for the building columns because their hollow structure allows them to perform better. However, you might need additional fittings and structural arrangements to work efficiently with steel tubes but the extra arrangement does not cost much. Therefore, by using the steel tubes you can have an efficient building process.

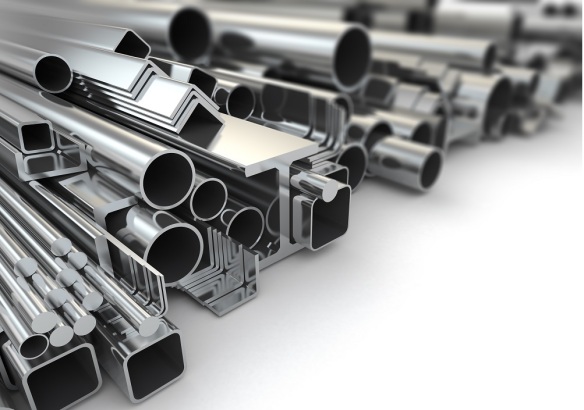

Railings:

In some places, steel tubes are used in the railings, and you can find them in stairs, decks, and warehouse flooring. Generally, many industries customize the steel railings as per needs and shapes. Similarly, these steel railings can also be welded together at all once. The only concern is that these can cause physical loads and stress over the structure. But a railing should provide a support system and be light in weight compared to other building components. In this case, you can use steel tubes that are lower in weight, and their hollow shape offers a perfect strength-to-weight ratio. Steel tubes and MS chequered plate can be used in every residential and commercial industry.

Electrical trough:

If you take any electrical equipment that protects wires, cables, devices, and switches, they should be protected from damage. Especially if these equipment have to be placed near the condenser units, CCTV camera, and the electrical box, they are quite at risk. So, to prevent damage and safeguard the devices you need an electrical trough in the form of steel tubes to reroute and prevent them from moisture.

Thus, these are the ways in which steel tubes are used for various purposes. So, buy quality steel tubes from Bharat Steels, the best JSW steel dealers in Chennai, to ensure your building’s safety.